CEEQUAL Very Good – Design and Construct Award

Version 5, January 2022 | Doha, Qatar

Client: Public Works Authority ‘Ashghal’

Consultant: Mott MacDonald Limited

Design & Built Contractor: HBK–PORR JV

Environmental Consultant: Conserve Solutions WLL

Design Consultants: VCE ZT GmbH & COWI A/S Qatar

Assessors: Marinko Augustinovic, HBK–PORR JV

Biliana Paskova, HBK–PORR JV

Dr Dila Ersenkal, Mott MacDonald Limited

Verifier: Karl Pitman, Pitman Associates Ltd

Project Summary

Musaimeer Pump Station and Outfall (MPSO) project area is located nearshore to the southwestern area of Doha, that has experienced rapid expansion of growth in recent years, with ongoing developments. The need to increase drainage capacity to accommodate storm water runoff and address flooding challenges has become the cornerstone in the development of the project.

MPSO project organization comprises of Ashghal, Public Works Authority (PWA) project management team, Project Management Consultant (PMC) Mott MacDonald and HBK-PORR as the main Contractor. These entities work collaboratively to achieve and sustain high performance in health, safety, environmental (HSE), and sustainability management.

MPSO is one of the unique infrastructure projects of Ashghal which aims to provide a sustainable solution for the discharge of surface and storm water in the State of Qatar. The project consists of three key features: a pumping station with a capacity of 19.7 m3/s, a 10 km long, 3.7 m internal diameter under seabed outfall tunnel, an offshore riser shaft and 84 port diffuser field.

The other project elements include:

- 10 nos submersible pumps

- Power supply ancillary works including generator, screening, ventilation

- Water quality sampling and online monitoring

- Support facilities such as electrical, hydraulic and mechanical rooms, laboratory, and control room.

- This magnitude of a project entails critical construction works such as deep excavation, underground structural works, Tunnel Boring Machine (TBM) tunnelling operation, offshore operation, and underwater construction of diffuser field that have the potential to affect a broad spectrum of HSE and sustainability aspects. The Project established and implemented an effective environmental management system (EMS) to mitigate the environmental impacts while ensuring timely delivery of the project with highest compliance to health, safety, environmental, sustainability standards, contributing to the United Nations (UN) Sustainable Development Goals (SDGs).

Project Strategy

The vision for the MPSO project was ‘environmental and sustainability excellence’, not only in the operation of this strategically important asset but also during the design and construction phases. Prioritisation of environmental and sustainability management helped the project yield value far beyond its immediate benefits, and contribute to the Qatar National Vision 2030, that has embodied the United Nations (UN) Sustainable Development Goals (SDGs).

The MPSO project has adopted a sustainability driven strategy and implemented a wide range of practices that could be easily adopted by other projects. These practices have helped to create a sense of ownership of sustainability within the whole project team, enabling them to work together towards achieving and delivering a socially inclusive, sustainable asset for Qatar, contributing to the UN SDG 17.

The following environmental and sustainability considerations have been integrated into the project lifecycle to achieve the best outcomes not only for the project, but for the Qatar nation as well:

- Consideration of climate change impacts and building resilient structures

- Minimising the carbon footprint of the project

- Inclusion of future projections to accommodate the future needs

- Discharging storm water back into the water cycle in a controlled manner

- Coastal management and protection

- Minimising the impacts on marine water quality and ecosystems

- Achieving the required dilution and mixing levels under all current scenarios for full range of operating conditions and flows

- Minimising changes in ambient concentrations and impacts on sensitive habitats such as corals and seagrass

- Using innovative technologies leading to efficient resource utilisation, minimised environmental impacts, cost savings and economic benefits.

- In addition to the design-specific achievements of the project, the project also has resulted in other achievements to date, including but not limited to the following:

- High professional dredging and marine works with insignificant impacts on seawater quality and marine ecology

- Recognition of the project through published papers and presentations on environment and sustainability

- Successful internal, external, and client audits that were responded to by the project

- Systematic and integrated approach in implementing environmental and sustainability management via standardised management tools that could be easily adopted by other projects

- Extremely high environmental and sustainability awareness and commitment of all project personnel

- Seawater quality baseline to ensure future operational environmental compliance

- Comprehensive environmental monitoring program

- Daily environmental performance evaluation to ensure compliance and trend analysis of findings

- Weekly environmental/sustainability trainings

- CEEQUAL compliance workshops

- Provision of comprehensive environmental and sustainability trainings to Ashghal graduates and capacity building for future generations

- Project-specific initiatives such as annual beach clean-up, plastic-free pledge, use of ceramic tableware and metal cutlery to avoid use of plastics, national day celebrations embracing the Equality, Diversity, and Inclusion (EDI) principles.

Project Management

Ashghal, as a leading government organisation in Qatar, has demonstrated the importance of responsible environmental management and commitment to sustainability by setting specific environmental and sustainability requirements for the MPSO project, which has led to the development and implementation of an Environmental Management System (EMS) in accordance with best practice such as ISO 14001:2015 and compliance with international sustainability rating scheme, CEEQUAL for the MPSO project.

Top management commitment has been the most significant factor in driving and achieving an effective environmental and sustainability management for the MPSO project. Having a shared vision of achieving ‘excellence’ in the environmental and sustainability management and recognition of the importance of the integration of this vision into the project lifecycle has led to the achievement of high performance for the MPSO project and also resulted in a range of other benefits.

- Alignment of the project’s objectives with Qatar National Vision 2030 and the United Nations Sustainable Development Goals (UN SDGs)

- Addressing the urgent flooding challenges that Qatar has been facing

- Opportunities to implement sustainable and innovative solutions to minimise adverse impacts and to achieve positive outcomes

- Improved environmental and sustainability performance

- Management of environmental aspects effectively

- Better use of energy and resources

- Economic benefits and significant cost savings

- Reduced legal, reputational, environmental and other risks

- Improved and strengthened stakeholder confidence and trust

- Enhanced social outcomes, and improved life quality of communities affected by flooding

- Value add for Qatar nation.

The recipe for success in achieving high standards for environmental and sustainability management has been the commitment by all parties involved in the project, collaborative approach, and the open dialogue between all project stakeholders, including Ashghal, PMC, and the Contractor, creating solutions together. PMC and Contractor top management has played a significant role in the successful implementation and maintenance of the established project management approach that prioritises environmental and sustainability management, by providing adequate financial resources and intangible resources such as leadership, commitment of time, encouragement of employees that facilitate the adoption and maintenance of the sustainable practices.

People and Communities

The main purpose of the MPSO project is collection and sustainable discharge of stormwater and groundwater flow from the key catchment to avoid flooding enhancing the communities’ living quality.

The location of the pumping station is strategically selected remote from the residential communities which eliminated almost all the potential impacts associated with dust, noise, and air quality. The project’s stakeholders which are mainly the national authorities, and the nearby industrial parties were also consulted- and engaged with to obtain required permits and approvals.

The potential construction impacts due to the dust, noise, and waste were properly mitigated by performing the initial baseline studies and implementation of a comprehensive Construction Environmental Management Plan (CEMP) supported by rigorous site-wide environmental monitoring programme. The operational impacts were assessed during the concept stage and these factors were incorporated in the design which was later constructed.

The measures taken included:

- Comprehensive nose and air quality monitoring and reporting programme in place

- Regular dust suppression on ground and stockpiles by reusing treated water from tunnelling works to prevent dust nuisance issues

- Continuous monitoring and regular scheduled inspections of machinery and equipment for noise and emission levels to mitigate noise and air quality concerns

- Best site housekeeping practices to ensure a good presentation of the site and to mitigate dust and temporary traffic concerns

- Selection of Earth Pressure Balance Type Tunnel Boring Machine (EPB TBM) for Tunnelling instead of slurry one, to avoid generation of slurry production

- Acoustic enclosures and treatment for noise concerns.

Land Use and Landscape

Through various desk and site studies, 22 options of proposed design methodologies and site locations were analysed based on factors such as site suitability, environmental & social impacts, technical feasibility and cost. Final concept allocates the project site at the seashore, in already urbanized industrial area. To avoid disturbance of seabed, 10 km outfall drainage tunnel was designed to be constructed 15m below the seabed by TBM method.

In-depth Environmental Impact Assessment (EIA) for the finalized design methodology unveiled all potential impacts during the concept design stage itself which is considered and mitigated through design. Geotechnical studies have also been conducted to determine geotechnical hazards and risks for which mitigation measures were developed and implemented.

Flood resilience is one of such features where the pumping station is actually designed for. Comprehensive HAZOP/CHAZOP studies were undertaken by the project team to evaluate all potential flooding hazards that could affect equipment, buildings, and other assets. The most applicable design mitigation measures and recommended actions were identified and reported. The design integrated specific measures to reduce surface water run-off and mitigate flood risks from a 1 in 50-year storm event.

The Historic Environment

Baseline survey of the historic environment was undertaken as part of the Environmental Impact Assessment (EIA). Project site is located in an area which has been subject to high levels of construction activities and disturbance by others and was void of any previous historic buildings or establishments. With these aspects considered, it was determined that the site is of no archaeological interest.

Ecology and Biodiversity

MPSO project works identified proximity with terrestrial and marine ecology due to the land works and marine works. To minimise the potential impacts on the environment, the authorities have requested the project to consider building an outfall chamber to discharge the collected stormwater into the marine environment in a controlled manner, to achieve the required dilution and mixing levels under all current scenarios for full range of operating conditions and flows.

Through the design workshops held, the length of the outfall chamber below the seabed was extended from 7 km to 10 km, away from the sensitive receptors around the project location. The methodology for constructing the outfall chamber has also been selected as a tunnelled outfall under the seabed, instead of an outfall pipeline with dredged trench on the seabed to reduce the potential negative impacts on the marine environment.

The Construction Environmental Management Pan (CEMP) developed for both onshore and offshore works incorporated Biodiversity and Ecology Management Plan to address the potential impacts due to the construction activities. Various measures were implemented on-shore and off-shore to mitigate the potential adverse impacts on ecology and biodiversity.

On-Shore:

- Implementation of a comprehensive environmental monitoring programme and regular monitoring of identified ecological features on and around the project footprint

- Preservation of acacia trees nearby the project site

- Protection of birds and honeybees’ colony on site

Off-Shore:

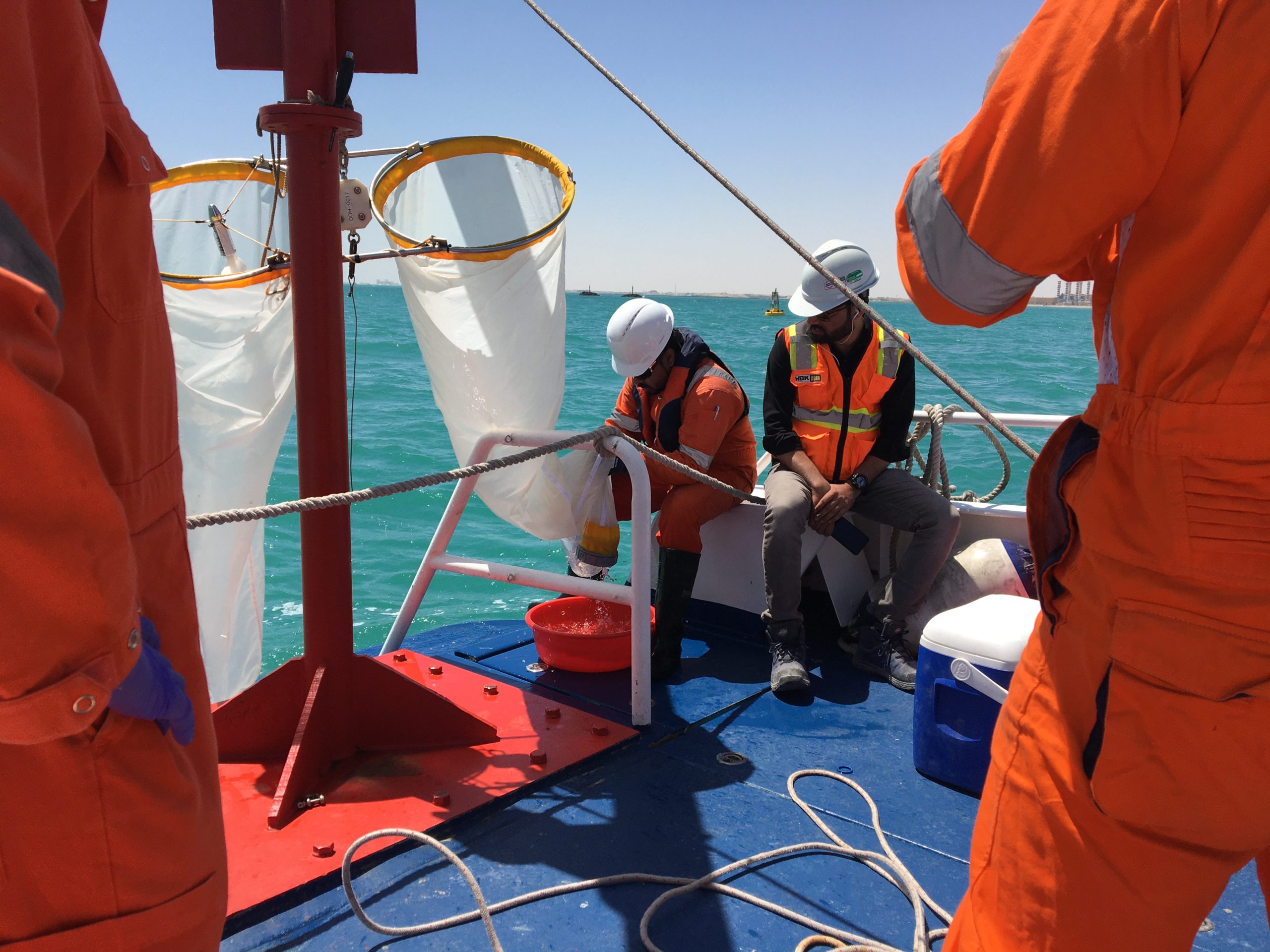

- Comprehensive marine environmental management programme including trainings, inductions, inspections, monitoring and reporting to prevent potential damage to ecological sensitive receptors

- Continuous online and weekly/monthly manual seawater quality sampling and analysis

The Water Environment

Storm water and ground water during operation

The overall design & operational concept of MPSO project serves to enhance the water resources by collecting the stormwater runoff and discharging it into the sea after filtration and primary treatment. This eliminates the uncontrolled overland flooding during rainfall events that would carry pollutants, debris, and other contaminants to the sea along the coastline resulting in waterbody pollution.

The design features of the pumping station include mechanical process equipment such as bar screens and disinfection systems to process the collected stormwater to allowable water quality limits before discharge to sea.

Marine water

As the operation of MPSO outlines discharge of the storm and groundwater from Abu Hamour tunnel 10km offshore in the marine environment, it was of crucial importance to establish the baseline data for the seawater quality that will allow comparison of operational data with the baseline environmental data that is being collected through the project life cycle to identify long-term trends. With that regard, a comprehensive seawater quality programme was established for the MPSO project that includes monthly seawater sampling and analysis and continual online monitoring of seawater quality through installation of oceanographic buoys. Monthly analysis reports are prepared and submitted to the authorities by the MPSO project to present the results of this monitoring exercise.

Water from tunnelling works

The project team equipped an onsite water treatment plant during construction to treat the dewatering water from the shafts and the TBM water to meet the allowable limits. Specific environmental permits were obtained from the Ministry of Environment and Climate Change (MECC). Most of this treated water was utilised on-site activities and the rest was discharged to sea without imparting pollution impacts. Daily, weekly, and monthly monitoring were conducted for the quality of the treated water to ensure no impacts were resulted due to construction activities.

Dewatering

In order to assure safety and stability of deep excavation works, dewatering around the construction site was required. Specific environmental permits were obtained from the Ministry of Environment and Climate Change (MECC), as well as Kahramaa. Daily, weekly, and monthly monitoring were conducted for the quality of the groundwater water to ensure no impacts were resulted due to construction activities.

Physical Resources – Use and Management (Energy, Water, Materials, Waste)

Energy:

The intensifying focus on matters such as climate change has provided a strong mandate for the PMC and the Contractor to deliver sustainable project outcomes, such as reducing the carbon footprint of the project; to enable contribution to address the bigger challenges that the global arena is facing. To achieve this goal, a range of mitigation measures have been implemented not only during the site related construction activities but also during the operation of the PMC and Contractor site offices as well.

The project encompasses a gravity-based tunnel for the discharge of accumulated stormwater with no pumping energy midway. The operational power demand was drawn by the establishment of an 11kV power connection from the national authority which again reduced on-site diesel generators.

In addition, the design includes the use of energy star equipment and energy-efficient light fixtures, extensive daylight use, materials selection emphasizing energy conservation through energy-efficient utilities through applicable codes, standards, and regulations.

Design for the Pumps was further optimized by introducing more VFDs to reduce the energy consumption and line losses.

The carbon footprint of the project was reduced through the energy conservation measures implemented during construction. Transport of the spoil from the project tunnelling works directly to the Al Khor municipality without any intermediate stockpiling has also led to avoiding CO2 emissions into the environment.

The tender design of the MPSO project required the use of cast in-situ roof. During the design meetings that focused on delivering a sustainable asset for Qatar, it was calculated that replacement of the cast in-situ roof with prefabricated elements would enable the project to achieve reduced CO2 emissions. Therefore, the decision was given to use prefabricated elements for the roof of the pump station, eliminating the need for 190 tons of form work and associated scaffolding, with a total cost saving of QAR 2,500,000.

Water:

During the construction phase, the project team actively pursued feasible water usage reduction measures such as reuse of treated TBM & dewatered water for dust suppression and cleaning activities. Accumulative water consumption data for potable, non-potable, reclaimed water, and wastewater was monitored and reported for weekly and monthly environmental compliance.

The water fixtures for the pump station were designed with international codes and standards for efficient plumbing such including British standards (BS), IBC (International Building Code), UPC (Uniform Plumbing Code); although number of operational staff for the MPSO is limited to 8 staff.

Material:

MPSO project contributed directly to the UN SDG 12 through embracing a transformative change in behaviour and adopting the culture of reuse and recycling not only during the project construction activities but also during the day-to-day operations of the site offices to preserve the natural resources and to minimise the waste generated by the MPSO project. Foreseeing the 100 years’ service life requirement of the project, viable material resource efficiency strategies were incorporated into the design and construction. The following measures were implemented:

- Usage of Precast tunnel segments for the 10km tunnel alignment with HPDE lining

- Launching shaft static/geometrical optimization and Pump Station excavation pit static/geometrical optimization uplift geometrical enhancement of the drop shaft resulted in reduced spoil production and reduced concrete usage on shaft construction

- Waste efficient procurement through exact quantity take-offs from the 4D BIM model eliminated overordering

- Procurement of concrete & steel with pre- and post-consumer recycled contents.

- Responsibly sourced wooden & timber products with FSC/PEFC Certificates for both temporary & Permanent works

- Procurement & usage of local/regional material (around 49% by volume)

- Low VOC/bio-degradable coatings and treatments wherever applicable.

Waste:

It was paramount for the MPSO project to implement Reuse and Recycling practices to contribute to the preservation of the natural resources and to minimise the waste generated by the MPSO project. With that objective in mind, the project has embraced a transformative change in behaviour and adopted the culture of recycling not only during the project construction activities but also during the day-to-day operations of the project site offices as well. The project team’s early realization of the forecasted tunnel muck diversion from the landfill enabled the project to reuse all the tunnel muck beneficially for a regional land reclamation project.

The project team saved 894 tons of waste from implementation of various waste management strategies during construction. The following measures were implemented:

- Implementation of a comprehensive Construction Environmental Management Plan (CEMP) that includes a detailed section on waste management and procedures to follow for waste hierarchy

- 100% of the excavated materials from the MPSO project tunnelling works have been reused at for regional coastal reclamation purpose

- 100% of the dredged materials from the dredging works were fully utilised during the backfilling works

- Establishment of a ‘Pledge for a Plastic-free Future’, signed by the Top Management as well as the project team members, demonstrating their commitment

- A dedicated waste segregation and storage areas at the MPSO project site is allocated to enable achieving high recycling rates for materials such as paper, cardboard, steel, wood, and plastics

- Introducing wide training programme and awareness sessions, information board posters on resource conservation, waste segregation, recycling, and responsible waste management.

And more

- Annual beach clean-up activity on a 4km long shoreline near the MPSO project site to raise awareness about plastic pollution and improve staff engagement. So far, the project has completed 3 beach clean-ups, respectively in 2018, 2020, and 2021.

- Celebration of annual sustainability week at the MPSO project site to emphasize the importance of environmental and sustainability management at site.

Transport

During construction the project team through proactive logistics and transportation planning achieved zero complaints/enforcements from the nearby stakeholders/public due to construction traffic movement/disruption. The following measures were implemented:

- Traffic flow design – temporary site works

- Designated traffic routes and time for construction vehicles

- Materials delivery strategies

- Site access road monitoring and maintenance.

- Sustainable transportation awareness programs were conducted for the project team which resulted in 30% of staff preferring carpooling to a single-occupancy vehicle.

Did the use of CEEQUAL deliver any financial benefits?

The mandate of the MPSO project management approach was to achieve economic benefits and reduce costs in a way consistent with the intended development objectives of the MPSO project by:

- Allocating the resources efficiently; considering the long design life and the durability of the materials and equipment

- Maximising the implementation of sustainable and innovative solutions

- Selection of equipment with low maintenance requirements

- Selection of the goods and services required for the project considering the positive impact on local providers

- Bringing benefits to the country by considering current and future projections

- Creating a value for the Qatar nation, raising the welfare of the communities affected by flooding.

Furthermore, by adaptation the above listed practices and effective resource allocation, use of sustainable and innovative solutions, consideration of durability and long design life, use of local goods and services providers to achieve economic benefits directly contributing to the UN SDG 12.

- 100 % of the excavated materials from the project tunnelling works have been reused for a regional coastal reclamation project, saving temporary stockpiling and double transport

- 100 % of dredged materials from the dredging works were fully utilised during the backfilling works to save material delivery and transportation

- Long design life and use of durable materials have been incorporated into the project design, as summarised below:- Concrete structures: 100 years

– Outfall tunnel: 100 years

– Marine underwater buried structures: 80 years

– Building: 50 years

– Mechanical parts: 20 years.

– Instrumentation and controls: 10 years - Utilisation of the precast beams and slabs for the construction of the MPSO project roof structure saving a total amount of 190 tonnes of steel formwork

- Use of a gravity system with low maintenance requirements for outfall and diffuser field has been used for the MPSO project

- The material selection process ensured that the materials selected for the MPSO project are of high quality, have no detrimental environmental or health impacts, and do not hinder construction in any way

- Segments required for the project were provided from the local segment factory

- Local supply of manpower and local companies for the dredging and marine works, oceanographic buoy supply and maintenance services, and others.

Estimated savings that can be attributed to CEEQUAL

Apart from project components such as time, scope and quality; project cost management is always considered as a key component of project management. One of the objectives of the MPSO project was to identify opportunities where the project could achieve cost savings and sustainable solutions, without compromising quality, health & safety, and environment.

There have been three major project achievements which resulted in significant cost savings for the MPSO project, as summarised below:

- Responsible selection of an alternative Tunnel Boring Machine (TBM) manufacturer – the selection of CREG/WIRTH TBM resulted in cost savings of QAR 5,000,000

- Following Design for Manufacture and Assembly (DFMA) principles and using advanced Building Information Modelling (BIM) technology, utilisation of the precast beams and slabs for the construction of the roof structure saving a total amount of 190 tons of steel formwork, with a total cost saving of QAR 2,500,000

- 100% of the excavated materials from the project tunnelling works have been reused for a regional coastal reclamation project with a total cost saving of QAR 11,257,370 for the Al Khor Municipality.

In your view, has CEEQUAL represented value for money?

Registering the project with CEEQUAL International enabled the MPSO project to incorporate sustainability considerations into the key project components and milestones. Adopting a sustainability-driven strategy and responsible approach to embedding the sustainability principles into the full lifecycle of the project has been crucial for the success of the MPSO project. The lessons learned from the MPSO project, and the good practices implemented at project site can be easily adopted by other projects, achieving higher sustainability outcomes.

Metrics

Embodied carbon emissions: 9,456,000 kgCO2 equivalent – 31% Reduction achieved

Re-used material: 121 tonnes (0,1% of total material used)

Potable water usage in construction: 70.227 m3 (57% of total water usage)

Re-used material (Wood Packaging): 187 tons (95% of total wood used or 8.6% of total waste on site)

Re-used material (Excavated spoil & Dredged material): 506,589 tons (100% of total excavated spoil)

Recycled material (Metals, Plastic, Cardboard and Paper): 707 tons (32.7% of total waste on site)

Locally supplied material: 49% of total material used

Potable water usage in construction (TBM and Construction) 211,247 m3 – 100% of total water usage(*all underground water in Qatar is saline. Saline water is not applicable for TBM operations)

Waste diverted from landfill: 1,267 tons (58.7% of total waste on site)

What were the main challenges for the project and how were these overcome?

The main challenge of the project in view of the CEEQUAL was the potential impacts to the marine environment due to dredging, drilling, and other offshore works. To overcome this challenge, a comprehensive testing and monitoring programme was developed and strictly followed.

The second challenge project faced was the very condense/tight project site space, which required extremely well planning of all construction and logistic works and implementation of housekeeping measures. The lack of spoil storage space on site lead to a huge obstacle to find solution for the excavated spoil from the construction of the 10 km long tunnel. Following proactive approach and good communication with the respective authorities, a sustainable solution to reuse the spoil for land reclamation was found and implemented.

Another challenge was the construction of the 10 km long, 3.7 inner diameter tunnel below the seabed with single access/exit point, under high water pressure conditions with potential health, safety, environmental and logistic hazards, which required 24/7, 365 days a year strict planning, control and monitoring of every single operation inside the tunnel.

Last but not least, the construction works continued despite the COVID-19 pandemic. Mott MacDonald and HBK-PORR JV management ensured that the appropriate level of actions was implemented to mitigate the effect of pandemic to staff, workers and public and such actions are aligned to Qatar Ministry of Public Health guidelines and each respective corporate policy for COVID19. In addition, Ashghal executive initiated monitoring of mental health condition of workers and staff to address the effect of COVID 19 to individual mental wellbeing especially for migrant workers who usually experience mental stress being away from their family amidst the peak of pandemic. The following are some of the measures implemented at project site and workers’ accommodation camp.

- Requirement for individual Ehteraz application to monitor current health condition

- Health bulletins for COVID19 through emails and notice boards

- Monitoring of body temperature

- Regular cleaning and disinfection of offices and meeting rooms

- Reducing number of passengers inside workers’ transportation vehicles to facilitate appropriate physical distancing

- Requirement to use face mask, encourage frequent handwashing and availability of hand sanitiser

- Provision of work from home arrangement for high-risk people (with chronic illness and 60 years of age)

What were the drivers and perceived benefits for undertaking a CEEQUAL assessment on this project?

Adopting best CEEQUAL practices and the strategic project management approach has enabled the translation of the overarching Qatar National Vision 2030 and the United Nations (UN) Sustainable Development Goals (SDGs) into a successful sustainability roadmap for the MPSO project. The following key factors were considered during shaping of the project sustainability roadmap:

- Focusing on the immediate challenges around flooding within Doha and delivering a sustainable, and socially inclusive asset for Qatar nation

- Addressing current and potential environmental, social, economic concerns associated with the MPSO project

- Developing a shared understanding of ‘sustainability’ while addressing the requirements of our client Ashghal and incorporating their points of views, priorities, needs and aspirations into the overarching project objectives with our client-focused approach

- Proactively adopting and implementing responsible practices to create opportunities to contribute to the UN SDGs

- Effective and innovative decision-making to choose the best direction for moving forward taking into consideration of future generations

- Raising awareness about the MPSO project’s environmental and sustainability commitment by promoting and fostering interactions with universities; publishing articles and presenting at international conferences, allowing a transparent communication on progress on the integration of sustainability into the project strategy

- Capacity building for future generations – Implementing a comprehensive training scheme for the Ashghal graduates at the MPSO project site, to increase the skillset of Qatari staff within Ashghal to expand their knowledge, awareness in a wide variety of project disciplines including environment and sustainability, to increase their involvement in the project through desktop training sessions and on-site visits of the project facilities such as the main project site, the marine works, the tunnelling works, and segment factory.

As can be seen from above, the ultimate goal of the MPSO project is not only to deliver a sustainable project with innovative solutions, but also creating opportunities for shaping the future of Qatar and contributing to the bigger picture by addressing the world-wide challenges that we are all facing.

What elements of this project highlight best practice and innovation?

Earth Pressure Balance Type Tunnel Boring Machine (EPB TBM) for Tunnelling

The outfall tunnel is constructed using an earth pressure balance type tunnel boring machine (EPB TBM). The EPB TBM used to construct the outfall tunnel mechanically removes the material by way of a cutter head and transports this material by special mechanisms to railway mount skips which then convey the material back to the main shaft for its removal and eventual disposal. The EPB TBM has specially designed features to allow safe and efficient excavation under difficult and challenging geological conditions. The EPB TBM is the largest potential source of spoil material on the project. Traditionally, this spoil has little recycling potential and is often transported to a landfill site with no further potential use. Detailed characterisation and analysis were conducted to identify the suitability of this spoil for possible reuse options. All of the tunnel spoil generated from the project was re-used to improve the poor local environmental conditions in Al Khor area, where the existing land allocated was mostly covered with shallow, stagnant water fed between low and high tides, leading to accumulation of debris and troublesome insects, causing damage and nuisance to the coastal area. The EPB TBM tunnel spoil from the MPSO project is used to improve the poor environmental conditions of the coastline area.

Cutter Suction Dredger (CSD) for Dredging Works

The project objective of minimising the potential environmental impacts of the dredging activities on the seawater quality and the marine ecology was one of the reasons for selecting a cutter-suction dredger (CSD) for the MPSO project, which is more environmentally friendly than other conventional mechanical dredgers.

The ‘Al Mahaar’ CSD used for the MPSO project has a cutting mechanism at the suction inlet, that loosens the seabed material and transports it to the suction mouth. The dredged material is then sucked up by a wear-resistant centrifugal pump and discharged through a pipeline back to the seabed. This results in the higher concentration of dredged sediment with the lowest possible turbidity is achieved. The ‘Al Mahaar’ CSD uses a real time GPS technology with high precision that enables to remove accurate thin layers of seabed so that the least possible quantities of material are dredged, minimising the risk of over-dredging disposal and associated high turbidity levels in the marine environment. The dredged material has been fully utilised in the backfilling works of the MPSO project.

During the dredging works, a closer attention to the seawater quality monitoring was paid and the frequency of the sampling and analysis was increased to ensure that potential impact of increased suspended sediment concentrations in the marine environment is avoided.

Oceanographic Buoys for Continual Monitoring of Marine Water Quality

Site-wide environmental monitoring has been implemented at specified representative sensitive receptor locations around the project site, for monitoring and measurement of environmental aspects such as air quality, noise, groundwater quality, wastewater quality, seawater quality, waste generation, and excavated materials.

As the MPSO project included the construction of a 10km outfall chamber below the seabed, it is of crucial importance to establish the baseline data for the seawater quality to allow for comparison of baseline environmental data with monitoring data that is being collected through the project life cycle to identify long-term trends. With that regard, a comprehensive seawater quality programme has been established for the MPSO project that includes monthly seawater sampling and analysis and continual online monitoring of seawater quality through installation of oceanographic buoys. Monthly analysis reports are prepared and submitted to the authorities by the MPSO project to present the results of this monitoring exercise. No detrimental environmental impacts were recorded during the offshore activities of dredging, riser shaft drilling, and backfilling.

BIM Modelling

4 D Building Information Modelling (BIM) reflecting to optimization of the material purchase and reducing the waste has enabled the MPSO project contribute directly to the UN SDG 12.

Quotes

The recipe for success in achieving high standards for environmental and sustainability management has been the commitment by all parties involved in the project, collaborative approach and the open dialogue between all project stakeholders, including Ashghal, PMC, and the Contractor, creating solutions together. PMC and Contractor top management has played a significant role in the successful implementation and maintenance of the established project management approach that prioritises environmental and sustainability management, by providing adequate financial resources and intangible resources such as leadership, commitment of time, encouragement of employees that facilitate the adoption and maintenance of the sustainable practices.

Gary Peach, Mott MacDonald Project Manager

The project has benefited from both Mott MacDonald’s and the Contractor’s high level of expertise in the environment and sustainability field, and the unique project lifecycle approach that allowed the environmental and sustainability aspects to be embedded into the project lifecycle since the earlier project phases, raising the bar in the construction industry. Prioritisation of environmental and sustainability management also helped the project not only achieve CEEQUAL certification but also yield value far beyond its immediate benefits, and contribute to the Qatar National Vision 2030, that has embodied the United Nations (UN) Sustainable Development Goals (SDGs).

Dr Dila Ersenkal, Mott MacDonald Technical Director – Environment and Sustainability

The MPSO project has adopted a sustainability driven strategy and implemented a wide range of practices that could be easily adopted by other projects. These practices have helped to create a sense of ownership of sustainability within the whole project team, enabling them to work together towards achieving and delivering a socially inclusive, sustainable asset for Qatar

Biliana Paskova, HBK-PORR JV QA/QC Manager

The ultimate goal of the MPSO project was not only to deliver a sustainable project with innovative solutions, but also creating opportunities for shaping the future of Qatar and contributing to the bigger picture by addressing the world-wide challenges that we are all facing.

Marinko Augustinovic, HBK-PORR JV Stakeholder Manager

BREEAM Infrastructure (formerly CEEQUAL) Case Studies

Browse the latest case studies from BREEAM Infrastructure

Stockholm Metro Nacka project awarded Excellent

Stockholm Metro Sofia access tunnel a BREEAM Infrastructure success

Stockholm Extended Metro access tunnel Sundstabacken achieves CEEQUAL Excellent rating

Preparatory works for the new water treatment system in Oslo achieves BREEAM Infrastructure Excellent rating

E39 Mandal øst – Mandal